How I Went From Acrylic to Compostable Sealants

Why I Switched to Natural Sealants for My Handmade Pieces

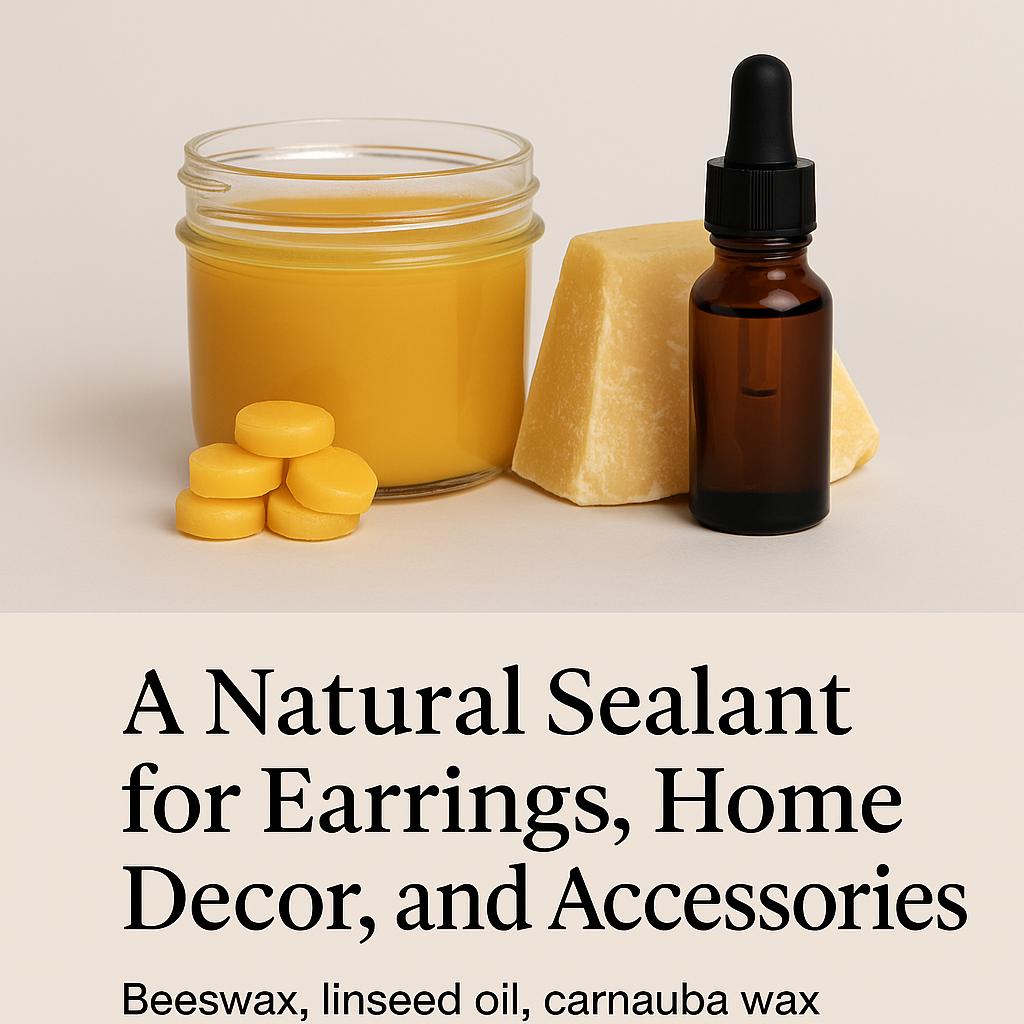

Recently, someone asked me on Instagram how I seal my earrings, home décor, and accessories. I always get a little excited when sustainability questions come up—so much so that I thought this one deserved its own blog post.

When I first started making paper earrings, I used an acrylic spray sealant. It was convenient, but I never felt entirely comfortable using it. The more I learned, the more I realised how misaligned it was with my values.

Here’s why I moved away from acrylic and enamel sprays:

The Sustainability Issues with Acrylic Spray Sealants

Volatile Organic Compounds (VOCs)

Acrylic sprays typically contain VOCs—chemicals that evaporate into the air as they dry. These contribute to air pollution and can cause health issues like headaches and respiratory irritation, especially when used indoors.

Petroleum-Based Ingredients

Acrylic polymers are made from non-renewable petroleum. Their production relies on fossil fuels and contributes to greenhouse gas emissions.

Non-Recyclable Packaging

Aerosol spray cans are difficult to recycle due to their mixed materials. Unless disposed of through a hazardous waste collection, they usually end up in landfill.

Environmental Toxicity

Overspray and improper disposal can harm soil and waterways, disrupting local ecosystems and microbial life—even in small amounts.

Health Hazards for Makers

Spray sealants require proper ventilation and protective gear. As a home-based maker (with a curious little one and a pup), this was far from ideal.

At first, I wasn’t sure what else I could use. But a bit of research and experimentation led me to a solution I loved: a blend of beeswax, linseed oil, and clove oil.

My First Natural Sealant: Beeswax, Linseed & Clove Oil

This blend gave me a sealant that was:

- Protective, nourishing, and gently antimicrobial

- Customisable, depending on the finish I wanted—more beeswax for a firmer barrier, more oil for a soft sheen

Beeswax Blend Curing Times

- Touch Dry: 4–6 hours

- Buffable: 12–24 hours

- Full Cure: 3–7 days, depending on temperature and thickness

Once cured, the finish had a soft, velvety feel I adored. But it wasn’t perfect.

The Problem with Beeswax for Some Items

The beeswax blend has a relatively low melting point (around 50–60°C), which is fine for earrings, bowls, vases and keyrings—but not ideal for coasters or items exposed to heat. That’s when I went back to the drawing board to create a more heat-resistant, compostable sealant.

The Gamechanger: Carnauba Wax, Tung Oil & Clove Oil

After more research, I developed a second blend using carnauba wax, tung oil and clove oil. It’s become my go-to for items that need a tougher finish, like coasters or trays.

Here’s why this sealant has been a gamechanger:

1. Durable, Water-Resistant Protection

Tung oil hardens as it cures, forming a water-resistant barrier. Carnauba wax, one of the hardest natural waxes, adds scratch resistance and repels moisture beautifully.

2. Safe and Non-Toxic

All ingredients are plant-based and free from synthetic additives. Once cured, the blend is safe to use around food and gentle on both people and the planet.

3. Naturally Antimicrobial

Clove oil offers natural antifungal and antibacterial benefits, making it especially useful in humid climates.

4. Enhances Natural Beauty

Tung oil draws out the rich tones and textures of the material, while carnauba wax adds a soft, refined sheen.

5. Long-Lasting Results

This blend offers deep nourishment from the tung oil and a hard surface seal from the wax—ideal for pieces that get handled regularly.

6. Customisable Finish

Depending on the item, I adjust the ratios: more tung oil for a matte look, more carnauba wax for extra shine. Just a few drops of clove oil help preserve the finish without overpowering the scent.

Carnauba Wax Blend Curing Times

- Touch Dry: 8–12 hours

- Ready to Buff: 24–48 hours

- Fully Cured: 7–10 days (or up to three weeks in cooler or humid conditions)

This natural, compostable sealant has allowed me to align my process more closely with my values—handcrafted, low-waste, and environmentally conscious. And now, when someone asks how I seal my work, I can point them here.

If you'd like me to share the exact ratios I use or how to apply it, let me know in the comments or send me a message—I'd be happy to share.